What is the electric power system?

From a general perspective, an electric power system is usually understood as a very large network that links power plants (large or small) to loads, by means of an electric grid that may span a whole continent, such as Europe or North America.

A power system thus typically extends from a power plant right up to the sockets inside customers’ premises. These are sometimes referred to as full power systems as they are autonomous.

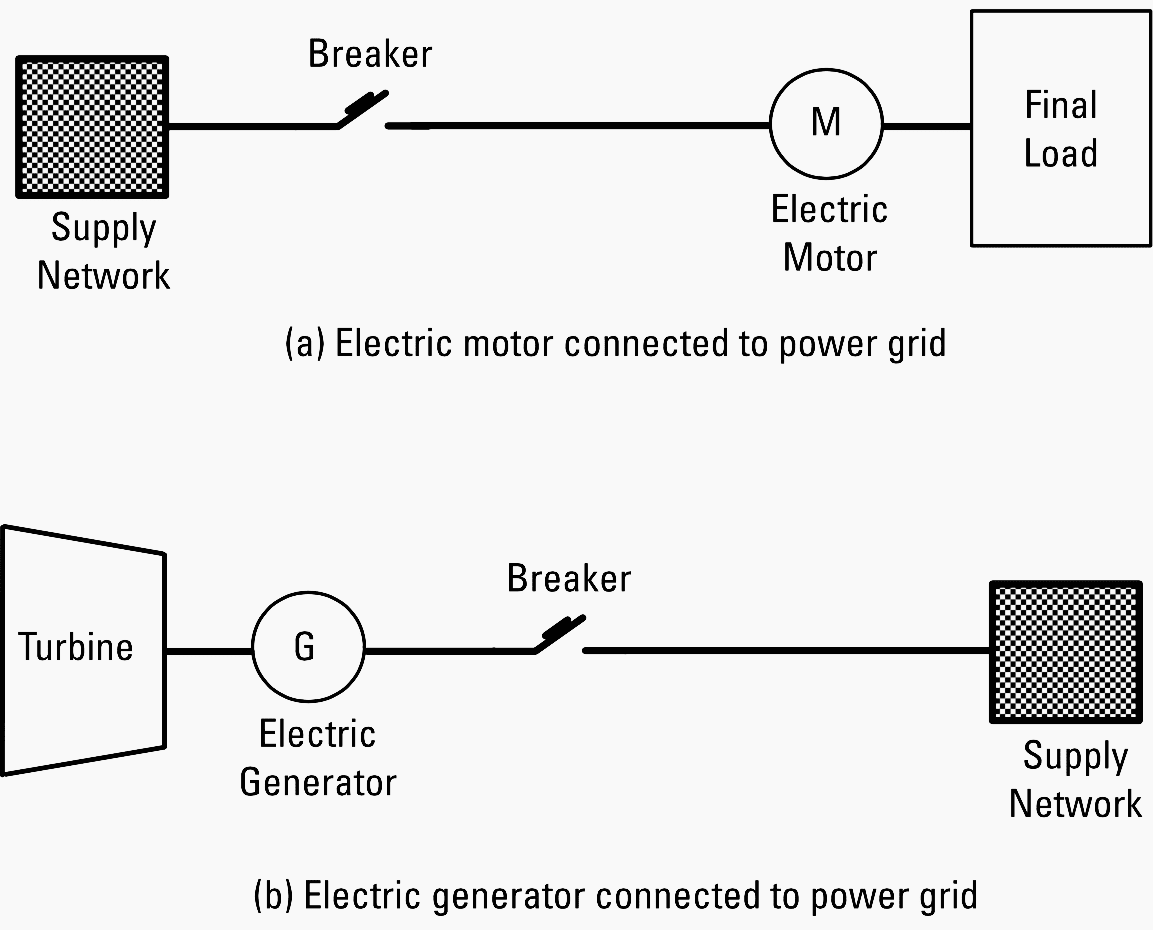

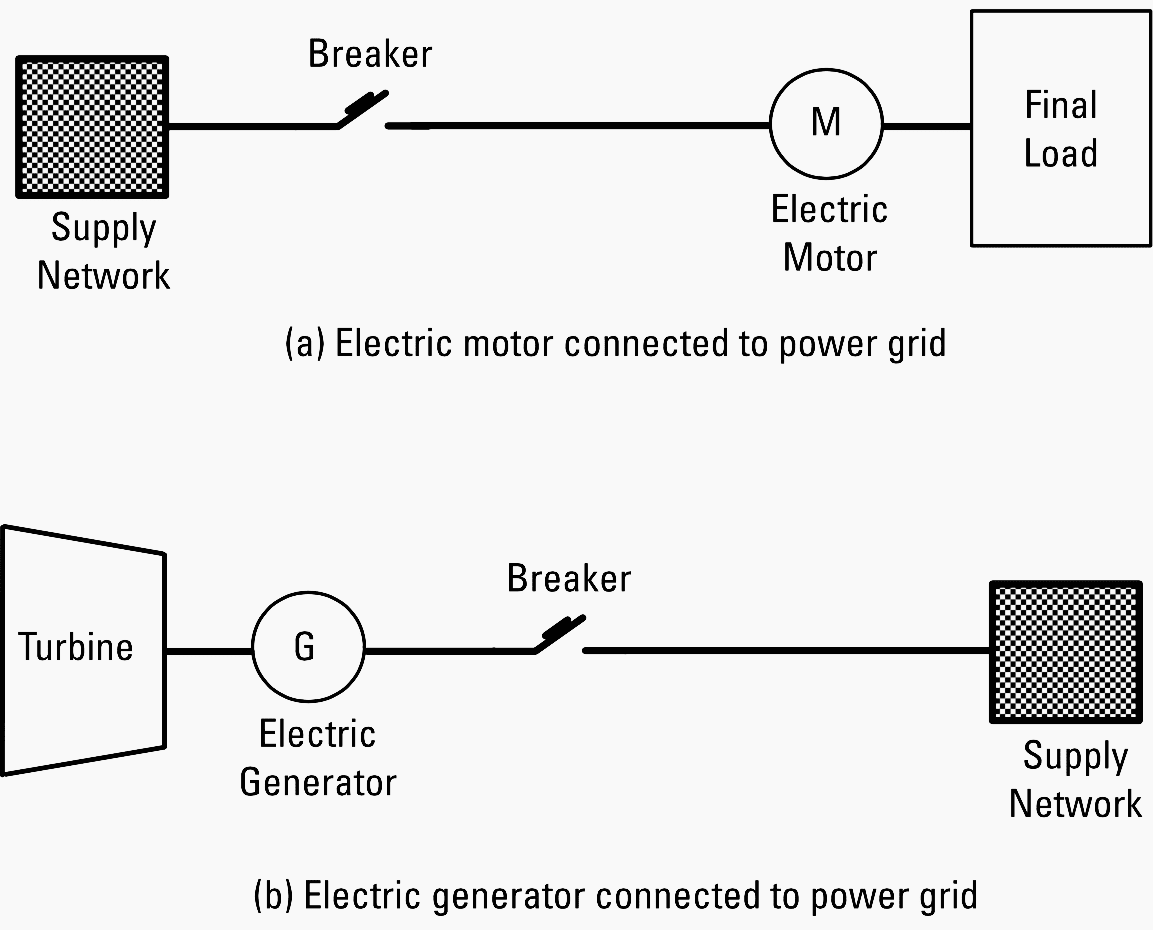

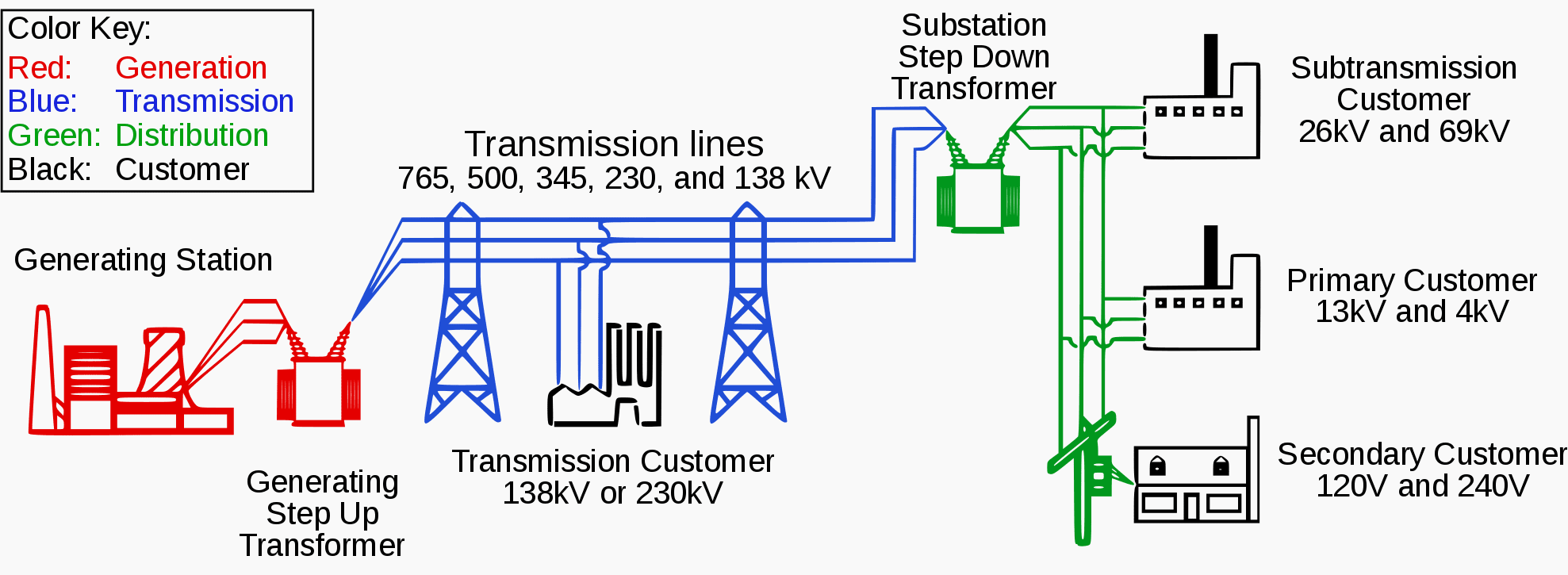

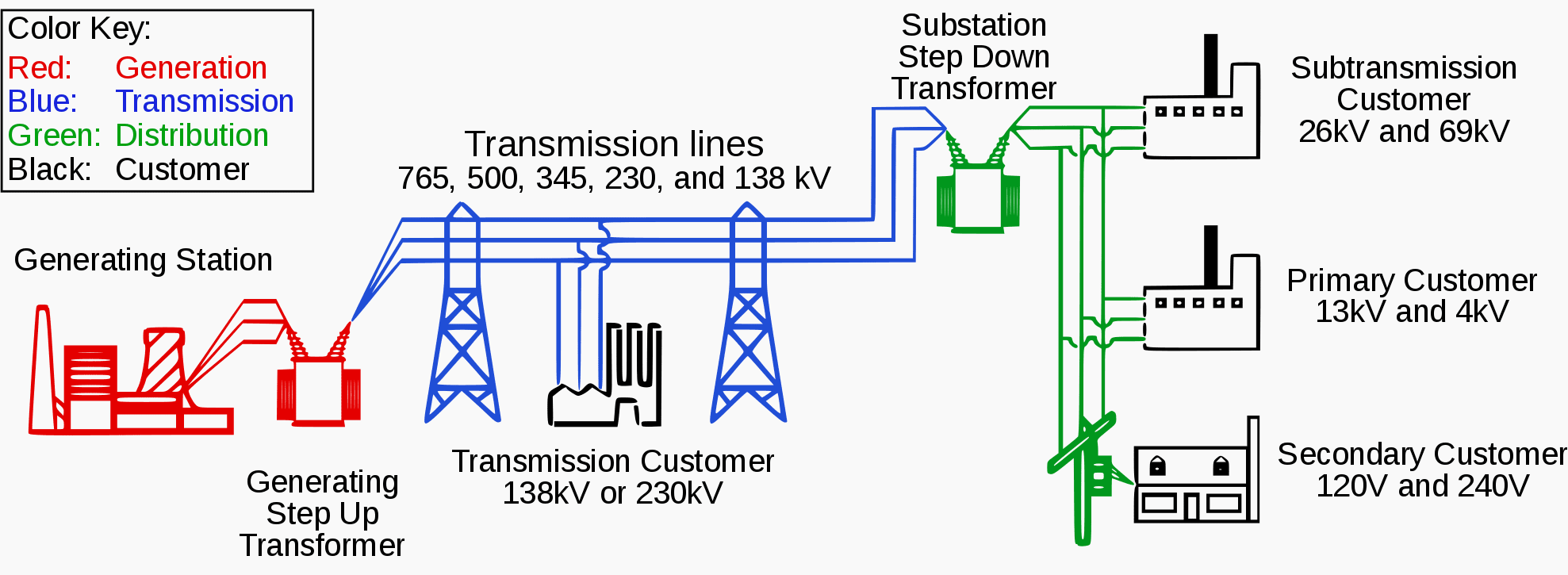

Smaller power systems could be made of part or sections of a larger, full system. Figure 1 shows several elements that operate together and are connected to a power supplying network.

Power systems that are supplied by an external electricity source or that produce (by conversion from other sources) electricity and convey it to a larger grid are called partial power systems.

Figure 1 (a, b) – Specific purpose power subsystems

The power systems that are of interest for our purposes are the large scale, full power systems that span large distances and have been deployed over decades by power companies.

Generation is the production of electricity at power stations or generating units where a form of primary energy is converted into electricity.

Distribution finally delivers the power (we could say locally when compared to the transmission system) to the final loads (a majority of which are supplied at low voltage) via intermediate steps at which the voltage is converted down (transformed) to lower levels.

The distribution system ends up at the energy consumption points or loads where power is used for its final purpose.

Watch Video – Overview of electric power systems

There are parts of the world in which the deregulation and privatization of the industry has already completely changed the industry landscape, while in others the impact is still to be seen.

Power Generation

Power plants convert the energy stored in the fuel (mainly coal, oil, natural gas, enriched uranium) or renewable energies (water, wind, solar) into electric energy.

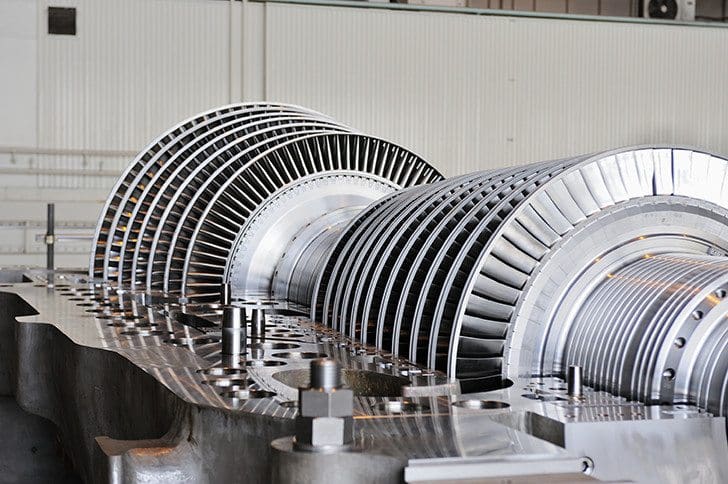

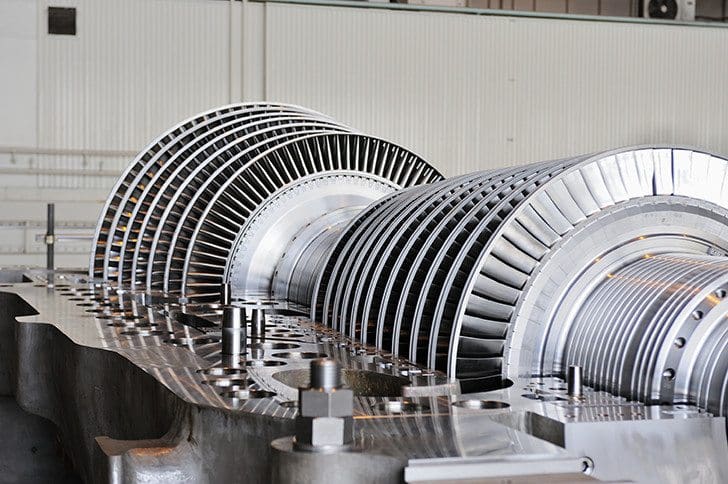

Conventional modern generators produce electricity at a frequency that is a multiple of the rotation speed of the machine. Voltage is usually no more than 6 to 40 kV. The power output is determined by the amount of steam driving the turbine, which depends mainly on the boiler. The voltage of that power is determined by the current in the rotating winding (i.e., the rotor) of the synchronous generator.

The output is taken from the fixed winding (i.e., the stator). The voltage is stepped up by a transformer, normally to a much higher voltage. At that high voltage, the generator connects to the grid in a substation.

Figure 2 – 472-megawatt steam turbine and generator (STG) for the Allen Combined Cycle Power Plant

Traditional power plants generate ac power from synchronous generators that provide three-phase electric power, such that the voltage source is actually a combination of three ac voltage sources derived from the generator with their respective voltage phasors separated by phase angles of 120°.

Wind turbines and mini hydro units normally employ asynchronous generators, in which the waveform of the generated voltage is not necessarily synchronized with the rotation of the generator.

DG refers to generation that connects into the distribution system, as opposed to conventional centralized power generation systems.

Small generators are constantly improving in terms of cost and efficiency, becoming closer to the performance of large power plants.

How does a Thermal power plant work?

Watch Video – How does a thermal power plant work

Transmission Systems

Power from generation plants is carried first through transmission systems, which consist of transmission lines that carry electric power at various voltage levels. A transmission system corresponds to a networked, meshed topology infrastructure, connecting generation and substations together into a grid that usually is defined at 100 kV or more.

Figure 3 – Electric power system

The electricity flows over high-voltage (HV) transmission lines to a series of substations where the voltage is stepped down by transformers to levels appropriate for distribution systems.

AC rms voltage levels

Preferred AC rms voltage levels are internationally standardized in IEC 60038:2009 as:

- 362 kV or 420 kV; 420 kV or 550 kV; 800 kV; 1,100 kV or 1,200 kV highest voltages for three-phase systems having a highest voltage for equipment exceeding 245 kV.

- 66 (alternatively, 69) kV; 110 (alternatively, 115) kV or 132 (alternatively, 138) kV; 220 (alternatively, 230) kV nominal voltages for three- phase systems having a nominal voltage above 35 kV and not exceeding 230 kV.

- 11 (alternatively, 10) kV; 22 (alternatively, 20) kV; 33 (alternatively, 30) kV or 35 kV nominal voltages for three-phase systems having a nominal voltage above 1 kV and not exceeding 35 kV. There is a separate set of values specific for North American practice.

Medium voltage (MV) as a concept is not used in some countries (e.g., United Kingdom and Australia), it is “any set of voltage levels lying between low and high voltage” and the problem to define it is that the actual boundary between MV and HV levels depends on local practices.

In Europe, overhead transmission lines are used in open areas such as interconnections between cities or along wide roads within the city. In congested areas within cities, underground cables are used for electric energy transmission. The underground transmission system is environmentally preferable but has a significantly higher cost.

Transmission lines are deployed with three wires along with a ground wire. Virtually all ac transmission systems are three-phase transmission systems.

Suggested Course – Power Engineering Course: Generators, Transformers and Transmission Lines

https://electrical-engineering-portal.com/academy/courses/generators-transformers-transmission-lines

Distribution Systems

Distribution segment is widely recognized as the most challenging part of the smart grid due to its ubiquity. Voltage levels of 132 (110 in some places) or 66 kV are usual HV levels that can be found in (European) distribution networks. Voltages below that (e.g., 30, 20, 10 kV) are commonly found in MV distribution networks.

MV grid topologies can be classified in three groups:

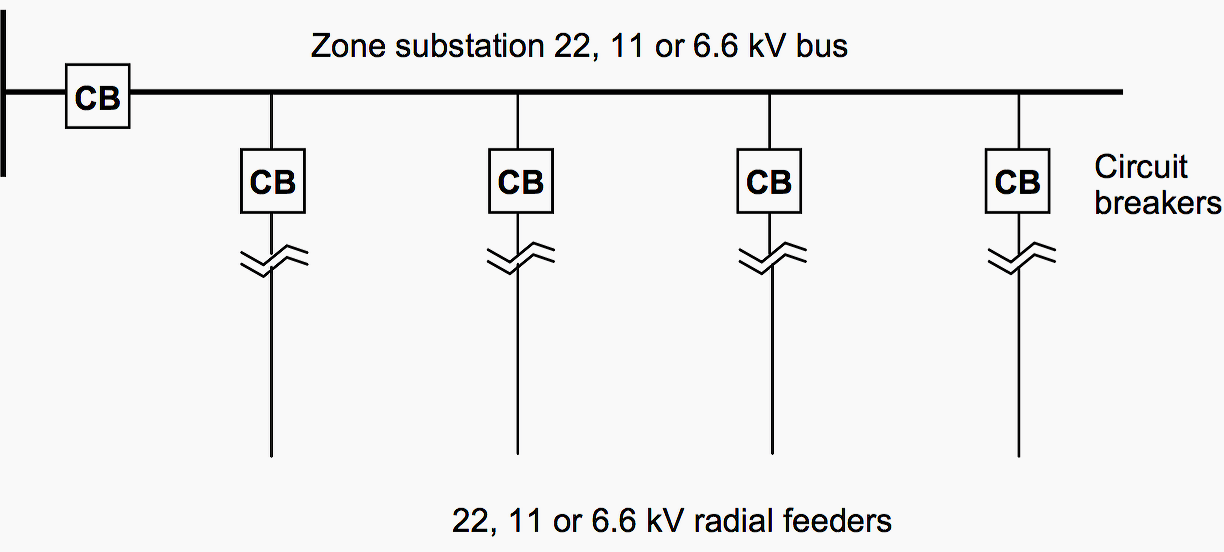

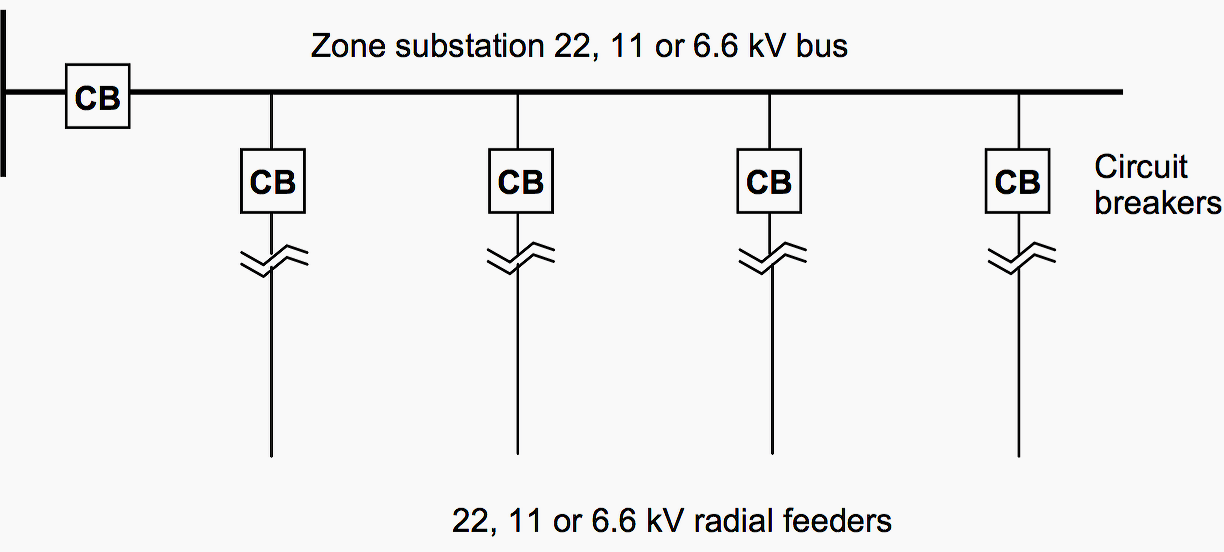

Radial topology

Radial lines are used to connect primary substations (PSs) with secondary substations (SSs), and the SSs among them. These MV lines or “feeders” can be used exclusively for one SS or can be used to reach several of them. Radial systems keep central control of all the SSs.

These radial topologies show a tree-shaped configuration when they grow in complexity. They are a less expensive topology to develop, operate, and maintain, but they are also less reliable.

Ring topology

This is a fault-tolerant topology to overcome the weakness of radial topology when there is a disconnection of one element of the MV line that interrupts electricity service (outage) in the rest of the connected substations. A ring topology is an improved evolution of the radial topology, connecting substations to other MV lines to create redundancy.

Independently of the physical configuration, the grid is operated radially, but on the event of a failure in a feeder, other elements are maneuvered to reconfigure the grid in such a way that outages are avoided.

Networked topology

Networked topology consists of primary and secondary substations connected through multiple MV lines to provide a variety of distribution alternatives. Thus, the reconfiguration options to overcome faults are multiple, and in the event of failure, alternative solutions may be found to reroute electricity.

LV grids present more complex and heterogeneous topologies than MV grids. The exact topology of LV systems depends on the extension and specific features of the service area, the type, number and density of points of supply (loads), country-specific and utility-specific operating procedures, and range of options in international standards.

An SS typically supplies electricity to one or several LV lines, with one or multiple MV-to-LV transformers at the same site. LV topology is typically radial, having multiple branches that connect to extended feeders, but there are also cases of networked grids and even ring or dual-fed configurations in LV networks.

LV lines are typically shorter than MV lines, and their characteristics are different depending on the service area.

Distribution Substations

Distribution substations are available in various dimensions and designs. A little rural substation may possess a nominal rating of 5 MVA, but a metropolitan station may exceed 200 MVA. Figures 7, 8, and 9 illustrate examples of small, medium, and large substations. Numerous utilities have extensively standardized substation configurations, transformer dimensions, relaying systems, and automation and SCADA (supervisory control and data acquisition) facilities.

The majority of distribution substation bus layouts are uncomplicated and exhibit minimal redundancy. Transformers with a capacity of less than 10 MVA are often safeguarded by fuses; however, fuses are also employed for transformers rated up to 20 or 30 MVA.

Typically, larger transformers are equipped with relay protection that activates a circuit switcher or circuit breaker. Relays frequently incorporate differential protection, sudden-pressure relays, and overcurrent relays. The differential protection and sudden-pressure relays possess sufficient sensitivity to identify internal faults and disconnect the circuit to mitigate further damage to the transformer.

Occasionally, relays function as a high-side grounding switch rather than an interrupter. Upon engagement of the grounding switch, a bolted fault is generated, which is then cleared by an upstream device or devices.

Figure 7 – Example suburban distribution substation

The feeder interrupting devices are typically relay-operated circuit breakers, which may be either standalone units or metal-enclosed switchgear. Numerous utilities utilize reclosers in lieu of breakers, particularly at smaller substations.

Station transformers are often pritected by differential relays that trip if the incoming current significantly deviates from the outgoing current. Relaying may additionally encompass pressure sensors. The high-side protection device is typically a circuit switcher, though it may also include fuses or a circuit breaker.

Utility procedures differ in the extent of safety margin incorporated into this calculation, and load growth can diminish the redundancy.

Figure 8 – Example suburban distribution substation

Most utilities typically employ a split bus configuration, with the bus tie connecting the two buses generally remaining open in distribution substations. The benefits of a split bus are:

Advantage #1 – Lower fault current

The primary reason for the openness of bus ties is as follows. In a two-bank station with identical transformers, the opening of the bus tie reduces the fault current by fifty percent.

Advantage #2 – Circulating current

In a split bus configuration, current cannot flow through both transformers simultaneously.

Advantage #3 – Bus regulation

Bus voltage regulation is more straightforward with a split bus. With the knot disengaged, managing parallel tap changers becomes more challenging.

Figure 9 – Example urban distribution substation

The closure of bus ties has some advantages, and numerous utilities employ closed ties under specific conditions. A closed bus tie is advantageous for:

Secondary networks: When feeders from each bus supply either spot or grid secondary networks, closed bus ties mitigate circulating currents inside the secondary networks.

Unequal loading: A closed bus tie facilitates the proper balance of load distribution on the transformers. If the feeders on a bus exhibit markedly distinct loading patterns, whether seasonal or daily, a closed bus tie facilitates the equalization of loading and aging between the two transformers.

The status of the bus tie, whether open or closed, hardly affects reliability. In the rare occurrence of a transformer failure, both designs permit the station to be modified, enabling a single transformer to supply both bus feeders.

Urban substations tend to possess more intricate bus configurations. These may encompass ring buses or breaker-and-a-half configurations. Figure 9 illustrates a substantial urban substation with feeders servicing secondary networks.

When feeders provide secondary networks, maintaining continuity to each feeder is not essential; however, it is crucial to ensure that the failure of any single bus section or piece of equipment does not incapacitate the network (an N-1 design).

Further Study – Fundamental concepts of schematic drawings for true field engineers

Fundamental concepts of schematic drawings for true field engineers (hands on HV schemes)

Reference: Telecommunication Networks for the Smart Grid by Alberto Sendin

Very good lecture for all classes of peoples.

Very enlightening.

Very rich article, really knowledge enriching.

Good electrical topics

Hello Edward, I am a student of the Russian University, a future power engineer, we were asked to read and translate your article into Russian. Now you can consider that your article has international recognition.

Hello Eduard, I am a student of the Russian University, a future power engineer, we were asked to read and translate your article into Russian. Now you can consider that your article has international recognition.

I looking for exams, how to calculate & layouts safety clearance to electric supply station electric equipment and impenetrable fences

Dear Evard,

Excellent article, veryuseful for power engineers. Keep doing good things. God bless you.

With warm regards,

L. Bangar Raju.,

This is such a nice write up, Edvard!

Keep up the good work.

Cheers,

Team Nama

I’m Electrical Power Engineer .Thanks Edvard for your very educative articles in the fields of Power Engineering .Your articles are really so helpful for us .Keep uploading more articles .we are so grateful for your great work.God bless you

Thank you for everything you create for future generation. Like up to dated information for GIS I can have a chance to know.

Hi Edvard,

I am Electrical Power Systems Engineer and this website is amazing so keed up working so.I am learning new things here and i am thankful for that. I would like to cooperate in the future with cos i have innovative ideas also. Best regards !

thank you for this informativ presentation. You are great to do this Really appreciated!

Very informative. I love your articles.

hi bro its nice article keep up to good work article

thank you for all documents, there are very important in electrical power field

please complete them by calculation and simulation techniques

thank you

You’re welcome!